FLAT RATE SHIPPING - Under $100, $9.99 - Over $100, $14.99

|

||

|

||

|

||

|

||

| The tailgate chain support tabs are mig welded into position by our experienced welding department. The appearance of the welded joints on our tailgate assemblies far exceed the appearance of the welds that were once considered acceptable on mass produced tailgates We use the same quality and thickness steel that is used by today's "Big Three" auto manufacturers in all of our pickup and Bronco tailgates. |  | |

| A spot welding machine similar to those used on an assembly line, is used to weld the tailgate end channels to the tailgate skin. All of the welding necessary to assemble the original tooling tailgates is done at Dennis Carpenter Ford Restoration Parts in Concord, NC. A heavy stamping contractor operating in the US is responsible for producing the tailgate skins for Dennis Carpenter. | |

| ||

| B7C-8340700-A 1953-72 F-100 stepside tailgate

BAAA-8344456-SS 1953-72 stepside tailgate chains made of stainless steel. Includes chain covers.

8C-8343018-SS 1942-72 stepside tailgate hinges made of polished stainless steel. | |

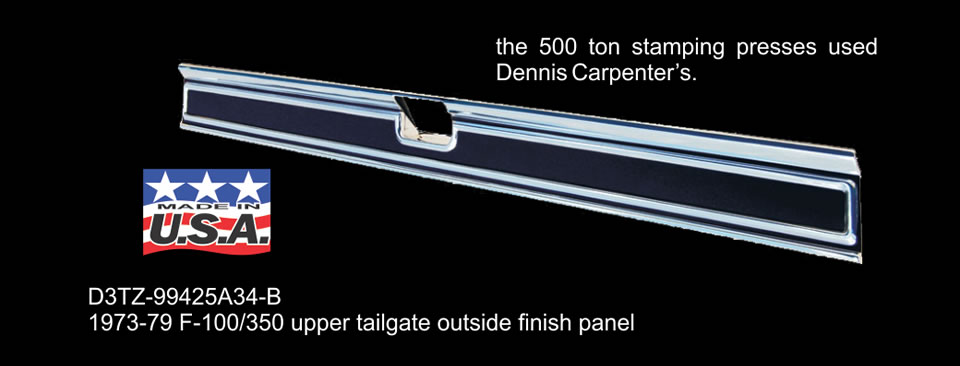

| A newly formed 1973-79 aluminum tailgate finish panel is pulled from one of the 500 ton stamping presses used at Dennis Carpenter's. We Use Original Ford Tooling To make Our 1973-79 & 1992-96 Tailgate Finish Panels Our tailgate finish panels are made from high strength 5000 series aluminum. |  | |

| ||

| Brushed Finish Exactly Like the Originals This original Ford finishing machine is used at Dennis Carpenter's to create the brushed finish on our 1992-96 Ford tailgate aluminum finish panels. | |

| ||

| ||

| ||

| ||

| ||